THERMO JETTER ULG-9000 Series

OUTLINE

![]()

Supplying Very Low Temperature Dry Air

No Need of Liquid Nitrogen

or a Large Sized System

Adopting the Unique Refrigerating System

“THERMO JETTER”

FEATURES

![]()

No need of LN2. Just supply electric power and dry air to realize very low temperature!

Even a small rate of 100L/min of air can realize -120°C in approximately 40 minutes. (250L/min max.)

Not like using LN2, it allows all-night operation without attendance of personnel for watching.

It enables stable temperature control as it doesn’t make condensation in the piping.

It realizes remarkable reduction of running cost with a small initial cost.

Adopting our unique single compression multi-cascaded condensation refrigerating system.

Use of a special dryer for controlling dew point temperature.

ULG-9300 reaches 200°C by micro-heater control.

The vibration free system is good to use in combination with precision equipment.

Energy saving design of small, light weight, quiet equipment needs no help of LN2.

Safe, simple and maintenance free pump less design

Optional air supply chamber enables local temperature control.

APPLICATIONS

![]()

-

THERMO JETTER ULG-9100

THERMO JETTER ULG-9100 For connection with analyzers/testers

For connection with analyzers/testers For frozen food manufacturer

For frozen food manufacturer For polymer manufacturer

For polymer manufacturer For mold cooling

For mold cooling For air cooled grinding (semi-dry process)

For air cooled grinding (semi-dry process) For storage of bio material (blood, cell, etc.)

For storage of bio material (blood, cell, etc.) -

THERMO JETTER ULG-9300 Environmental Test Type

THERMO JETTER ULG-9300 Environmental Test Type For analyzers/testers (cooling and heating)

For analyzers/testers (cooling and heating) For heat cycle tests of mounted device

For heat cycle tests of mounted device For environmental test (big change of temp.)

For environmental test (big change of temp.) For degradation process tests

For degradation process tests For connection with various equipment

For connection with various equipment

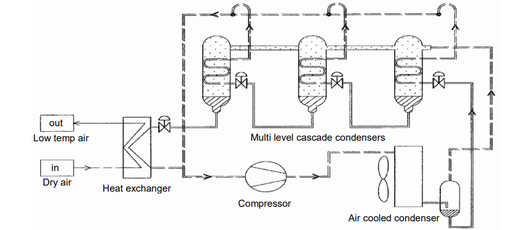

PRINCIPLE

![]()

Originally blended gas of different boiling points is condensed sequentially in the cascaded condensation system to achieve very low temperature.

Not like a conventional two-stage refrigerating system, it has only one refrigerator, saving energy and space, making light weight equipment. The simple structure reduces cost of maintenance.

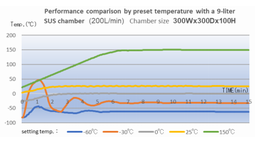

PERFORMANCE

![]()

-

Arrival time example to setting temperature at 200L/min. of air flow.

-

Reachable to low-temperature range by controlling air flow.

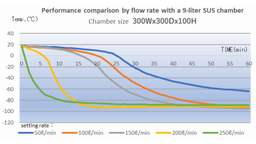

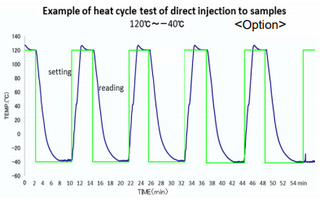

APPLICATION EXAMPLE

![]()

-

Reachable to low-temperature range by chamber content.

-

Heat cycle test example repeating cooling/ heating.

SPECIFICATIONS

![]()

| THERMO JETTER | ULG-9100 | ULG-9300 |

|---|---|---|

|

Weight and dimensions |

Approx. 200 kg 510(W)x740(D)x1110(H) mm |

|

|

Power Supply |

3-ph 200V 50/60Hz |

|

|

Rated Current |

9.8A | 12.3A |

|

Circuit Breaker |

30A | |

|

Compressor |

2.2KW | |

|

Heater |

N/A |

1 kW |

|

Cooling Performance |

Approx.500W(200L/min. at -95℃ output) | |

|

Air Flow |

From 30 to 250L/min (Variable) | |

|

Startup Time |

Approx. 40min (-120°C at the jet nozzle) |

|

|

Lowest Temperature |

-120°C (depending on conditions) |

|

|

Condensation Method |

Air Cooling |

|

|

Port (IN/OUT) |

IN: Rc3/8” female OUT: 3/8” Stainless Steel |

|

|

Temp. Control |

N/A |

-120 ºC ~ +200ºC Arbitrary setting available |

|

Utility |

Compressed Dry Air (0.4~0.6Mpa more than 150L/min air supply required for ≧100L/min) |

|

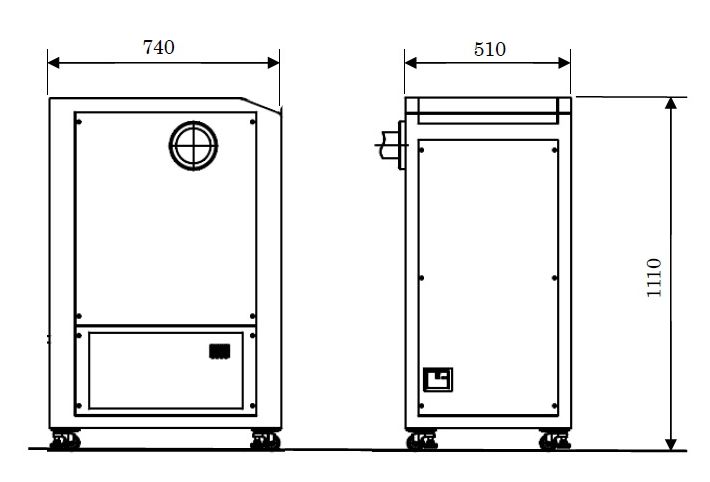

OUTER DIMENSIONS

![]()

-

OUTER DIMENSIONS & CONNECTION

OUTER DIMENSIONS & CONNECTION Air jet outlet can be connected to a chamber section of a tester directly to get efficiency of cooling specimens.

Air jet outlet can be connected to a chamber section of a tester directly to get efficiency of cooling specimens. Air jet outlet can be selected from A and B.

Air jet outlet can be selected from A and B. Please consult the manufacturer for connection.

Please consult the manufacturer for connection. Power supply required: 3-ph 200V 50/60Hz

Power supply required: 3-ph 200V 50/60Hz Air supply required: Industrial dry air

Air supply required: Industrial dry air -

OUTER DIMENSIONS & CONNECTION

OUTER DIMENSIONS & CONNECTION

Inquiries about THERMO JETTER ULG-9000 Series

TEL.+81-42-572-1397

(Monday to Friday, 9:00 am to 5:00 pm Japan Time)

FAX.+81-42-573-1520