FPS Abrasion Tester AB-2012

OUTLINE

![]()

AB-2012 FPS Abrasion Tester can perform

tests by controlling tangential force

between the test piece and the abrasive whee

in addition to the conventionalcontrol of slip

ratio, aiming more correlation to the real tires.

TEST ITEMS

![]()

Slip ratio regulation test

Slip ratio regulation test Friction force regulation test

Friction force regulation test

FEATURES

![]()

![]() Friction force regulation tests which were not available with conventional abrasion testers.

Friction force regulation tests which were not available with conventional abrasion testers.

Real-time measurement of test piece diameter for feed-back of the circumferential speed.

Real-time measurement of test piece diameter for feed-back of the circumferential speed. Control of abrasive wheel temperature without using a slip ring. (optional)

Control of abrasive wheel temperature without using a slip ring. (optional) Simplified test piece transport system using the swing arm.

Simplified test piece transport system using the swing arm. Improved test piece clamping system with a ratchet.

Improved test piece clamping system with a ratchet. Use of the accurately controlled talc feeding system for adhesion preventing. (Japan patent no. 4559617)

Use of the accurately controlled talc feeding system for adhesion preventing. (Japan patent no. 4559617) High repeatability of test conditions with Safety Walk used as abrasive.

High repeatability of test conditions with Safety Walk used as abrasive. Fully automatic tests of 64 (10-mm thick) or 32 (20-mm thick) test pieces.

Fully automatic tests of 64 (10-mm thick) or 32 (20-mm thick) test pieces. Two brushes clean the surface of the abrasive wheel to keep the conditions constant.

Two brushes clean the surface of the abrasive wheel to keep the conditions constant. Friction energy analysis available with the exclusive software.

Friction energy analysis available with the exclusive software.

APPLICATIONS

![]()

Abrasion tests of rubber materials for tire, belt, roller, etc.

Abrasion tests of rubber materials for tire, belt, roller, etc.

![]() ISO and JIS describes abrasion testers for rubber. However, difference of specimen shapes, abrasives and methods may give different results because of the different wear mode. An optimum tester must be selected for the final product of the material and its usage conditions. The FPS abrasion tester is specially designed to get material abrasion result best correlated to that of automobile tires.

ISO and JIS describes abrasion testers for rubber. However, difference of specimen shapes, abrasives and methods may give different results because of the different wear mode. An optimum tester must be selected for the final product of the material and its usage conditions. The FPS abrasion tester is specially designed to get material abrasion result best correlated to that of automobile tires.

MEASUREMENT ITEMS

![]()

![]() Specimen velocity (m/min)

Specimen velocity (m/min)

Abrasive wheel velocity (m/min)

Abrasive wheel velocity (m/min) Slip ratio (%)

Slip ratio (%) Load (N)

Load (N) Friction force (N) or torque (N・m)

Friction force (N) or torque (N・m) Specimen diameter (mm)

Specimen diameter (mm) Specimen surface temperature (°C)

Specimen surface temperature (°C) Abrasive surface temperature (°C) (optional)

Abrasive surface temperature (°C) (optional)

SOFTWARE (Touch Panel Screen)

![]()

![]() TITLE

TITLE

![]() This is the initial screen displayed at power-on.

This is the initial screen displayed at power-on.

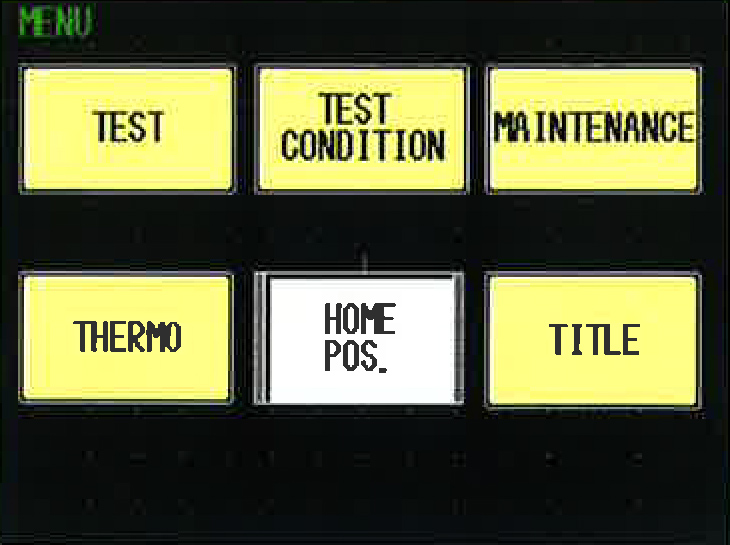

![]() MENU

MENU

![]() Select operation in the menu screen.

Select operation in the menu screen.

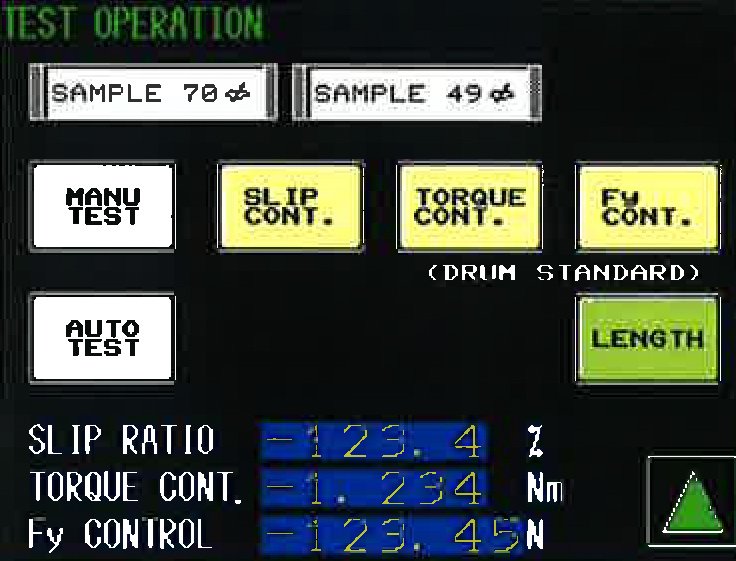

![]() TEST OPERATION

TEST OPERATION

![]() Select a mode, specimen dia., etc.

Select a mode, specimen dia., etc.

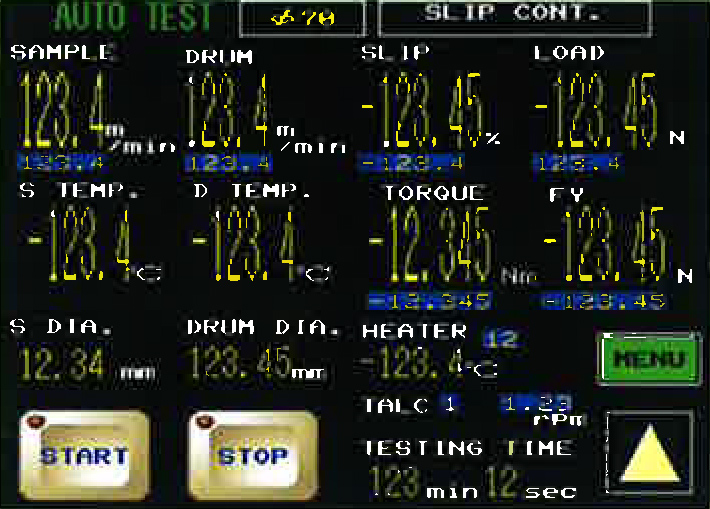

![]() AUTO TEST

AUTO TEST

![]() Displays measurement data.

Displays measurement data.

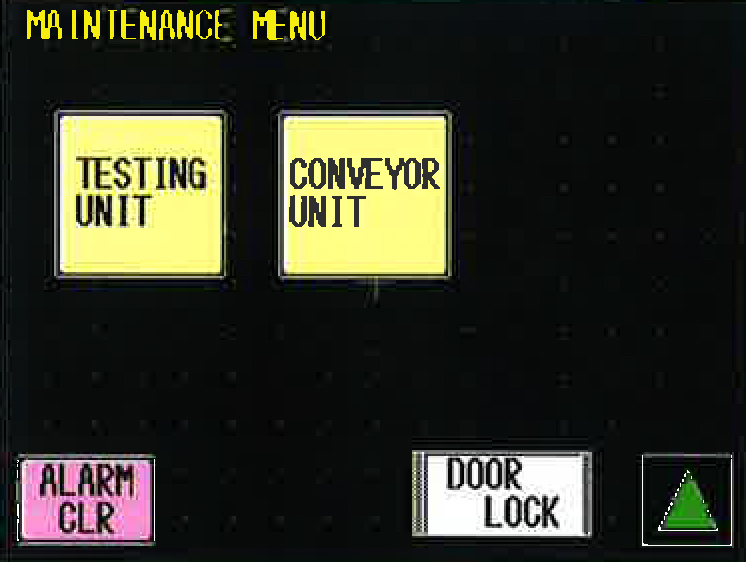

![]() MAINTENANCE MENU

MAINTENANCE MENU

![]() Enables operation of each part.

Enables operation of each part.

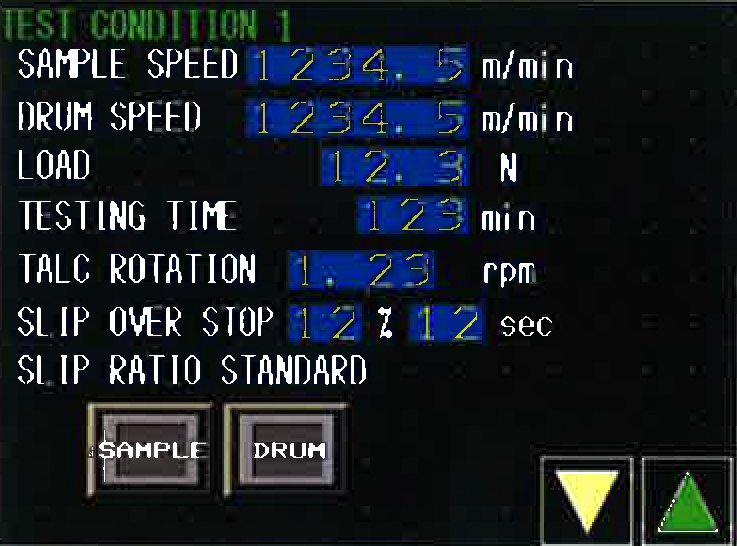

![]() TEST CONDITION 1

TEST CONDITION 1

![]() Makes condition setups.

Makes condition setups.

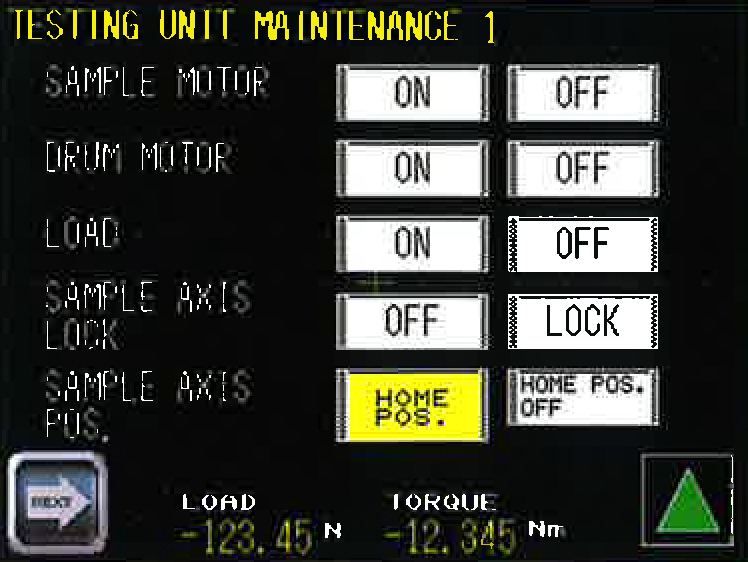

![]() TESTING UNIT MAINTENANCE 1

TESTING UNIT MAINTENANCE 1

![]() Operates the testing unit.

Operates the testing unit.

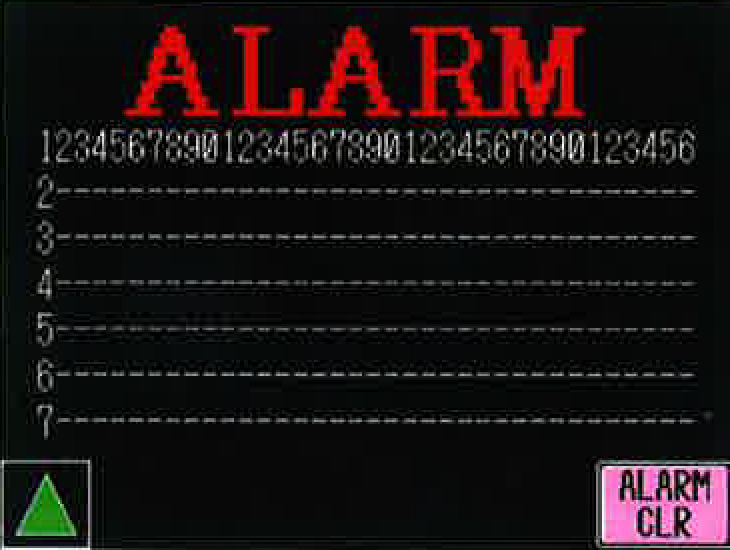

![]() ALARM DISPLAY

ALARM DISPLAY

![]() A message will appear upon an ALARM is encountered.

A message will appear upon an ALARM is encountered.

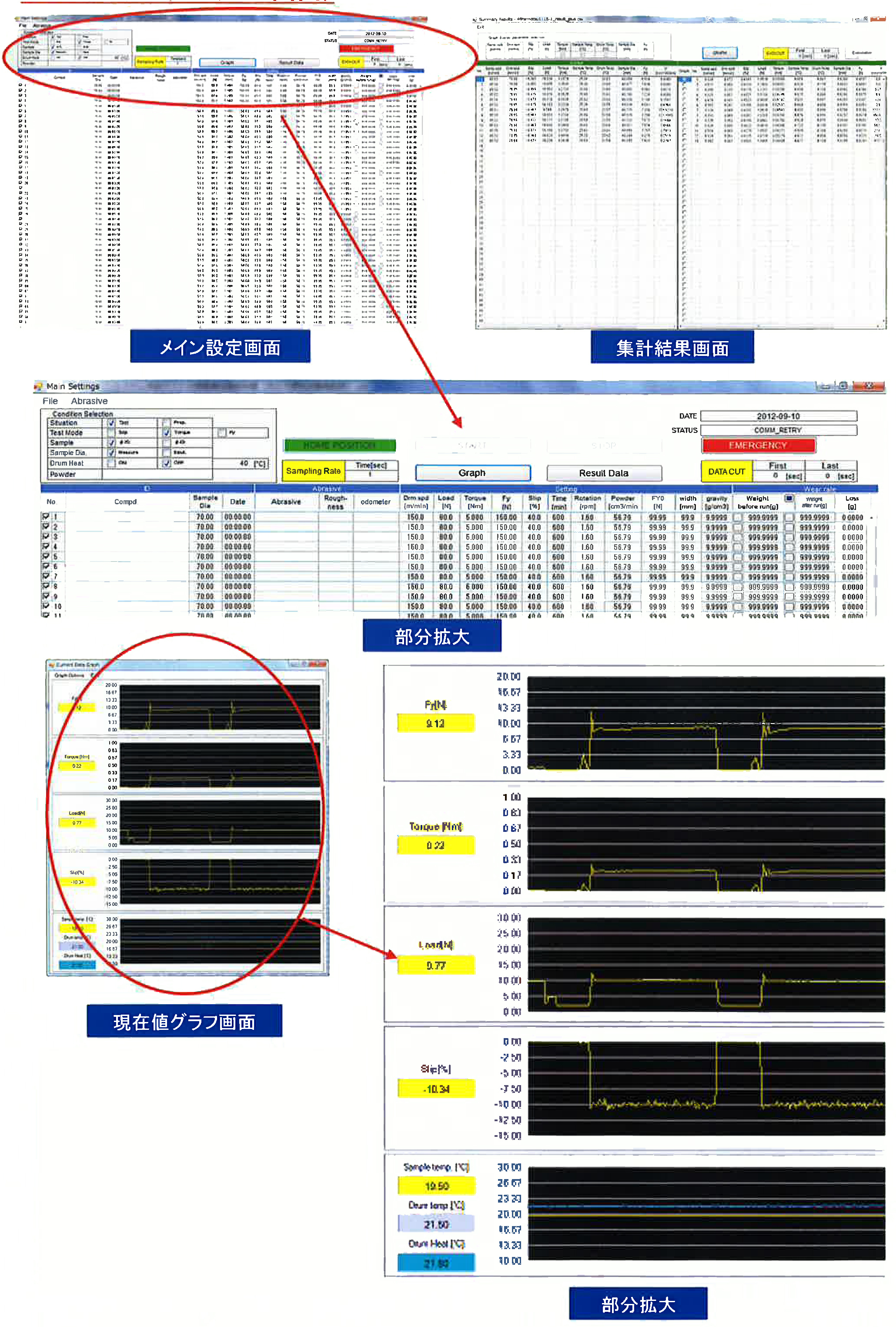

SOFTWARE (PC Screen)

![]()

It displays the current measurement data of Fy, Torque, Load, Slip Ratio, Sample Temp, Drum Temp and Drum Heat.

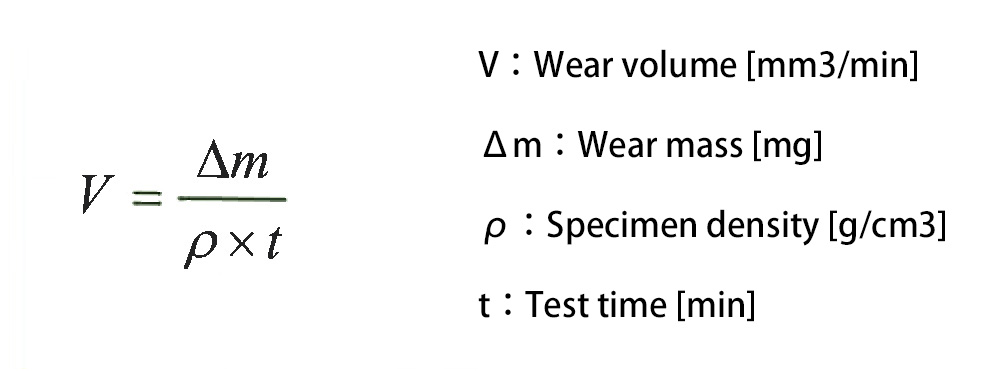

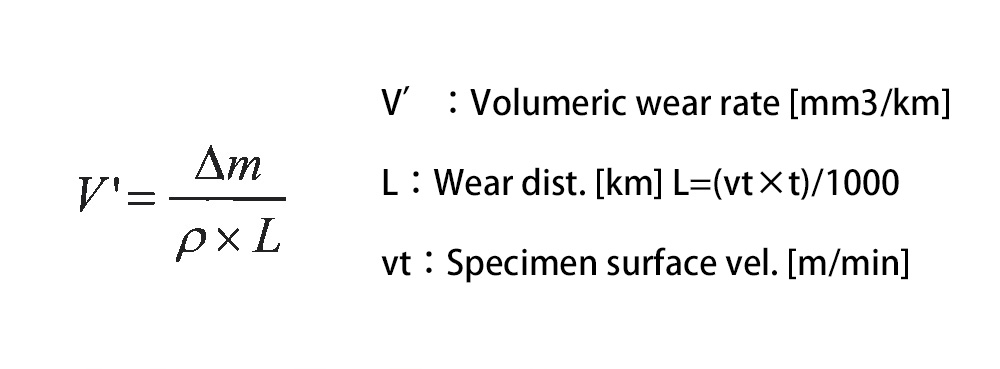

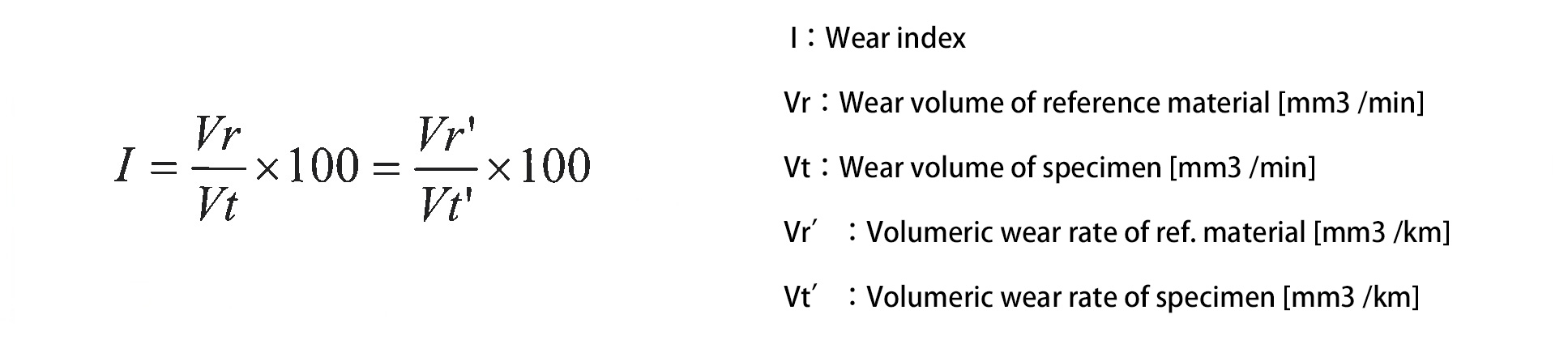

Tire Material Wear Test – How to Summarize the Results

![]()

![]() From the Standard (ISO, JIS)

From the Standard (ISO, JIS)

![]() Wear volume

Wear volume

![]() Volumeric wear rate

Volumeric wear rate

![]() Wear index

Wear index

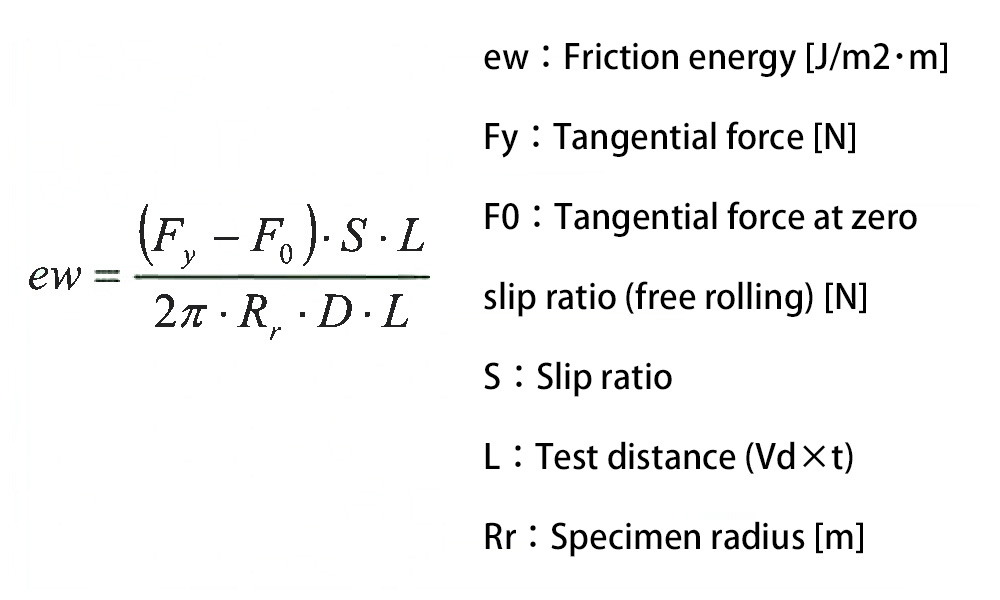

![]() Based on severity (Friction energy vs Wear volume per 1,000 km)

Based on severity (Friction energy vs Wear volume per 1,000 km)

![]() Friction energy

Friction energy

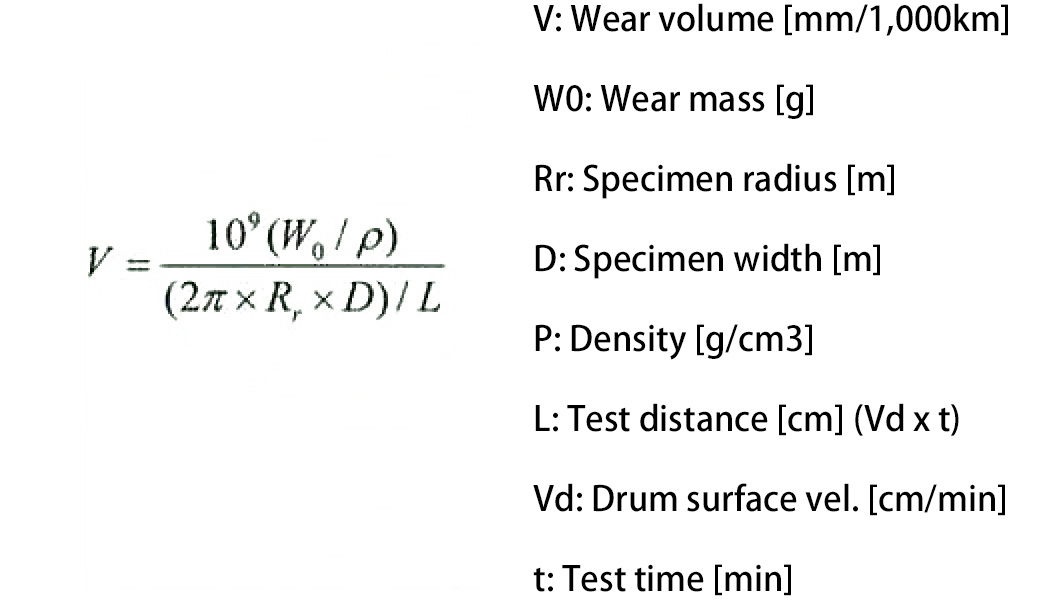

![]() Wear volume per 1,000 km

Wear volume per 1,000 km

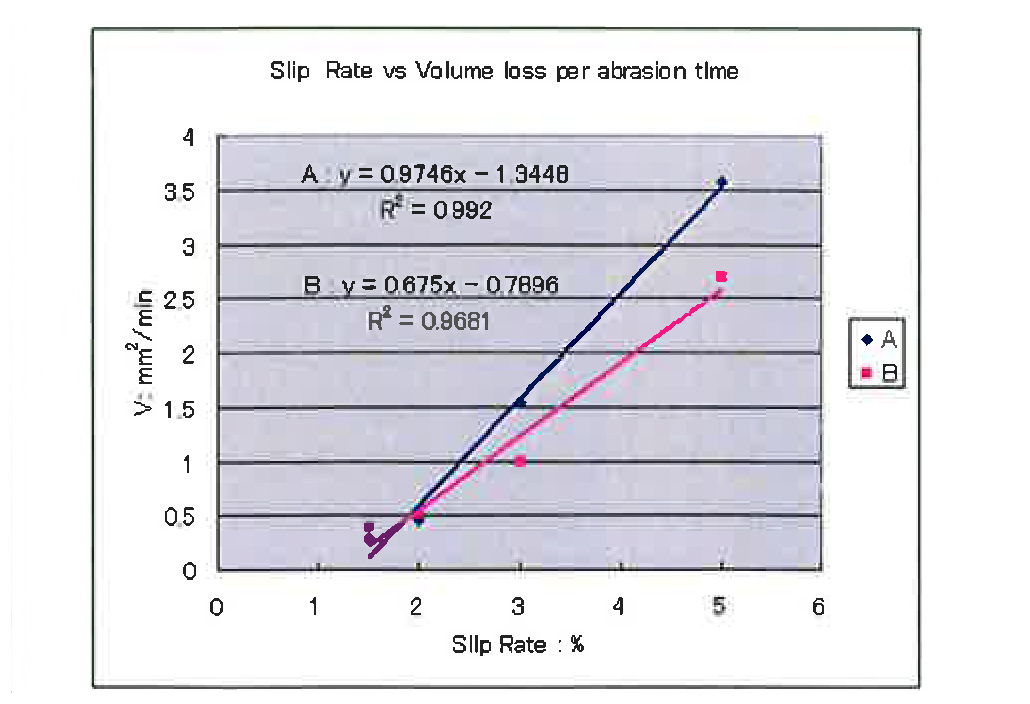

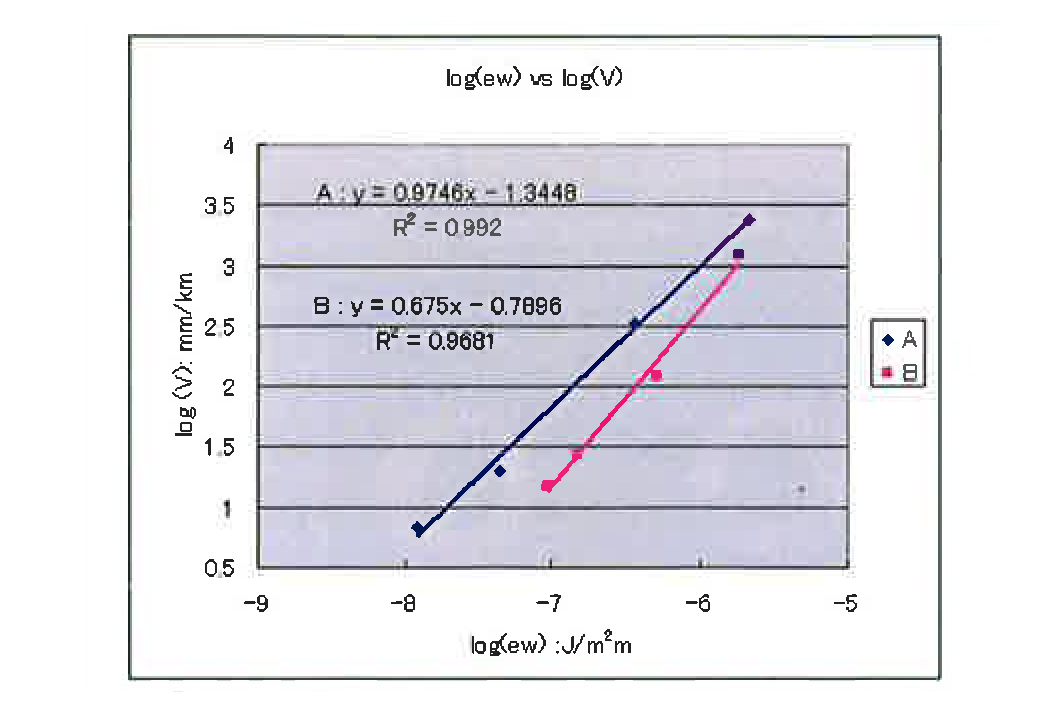

![]() An example: Comparison of different materials

An example: Comparison of different materials

![]() Slip Ratio VS Wear Volume

Slip Ratio VS Wear Volume

![]() Wear Volume/1,000km VS Friction Energy

Wear Volume/1,000km VS Friction Energy

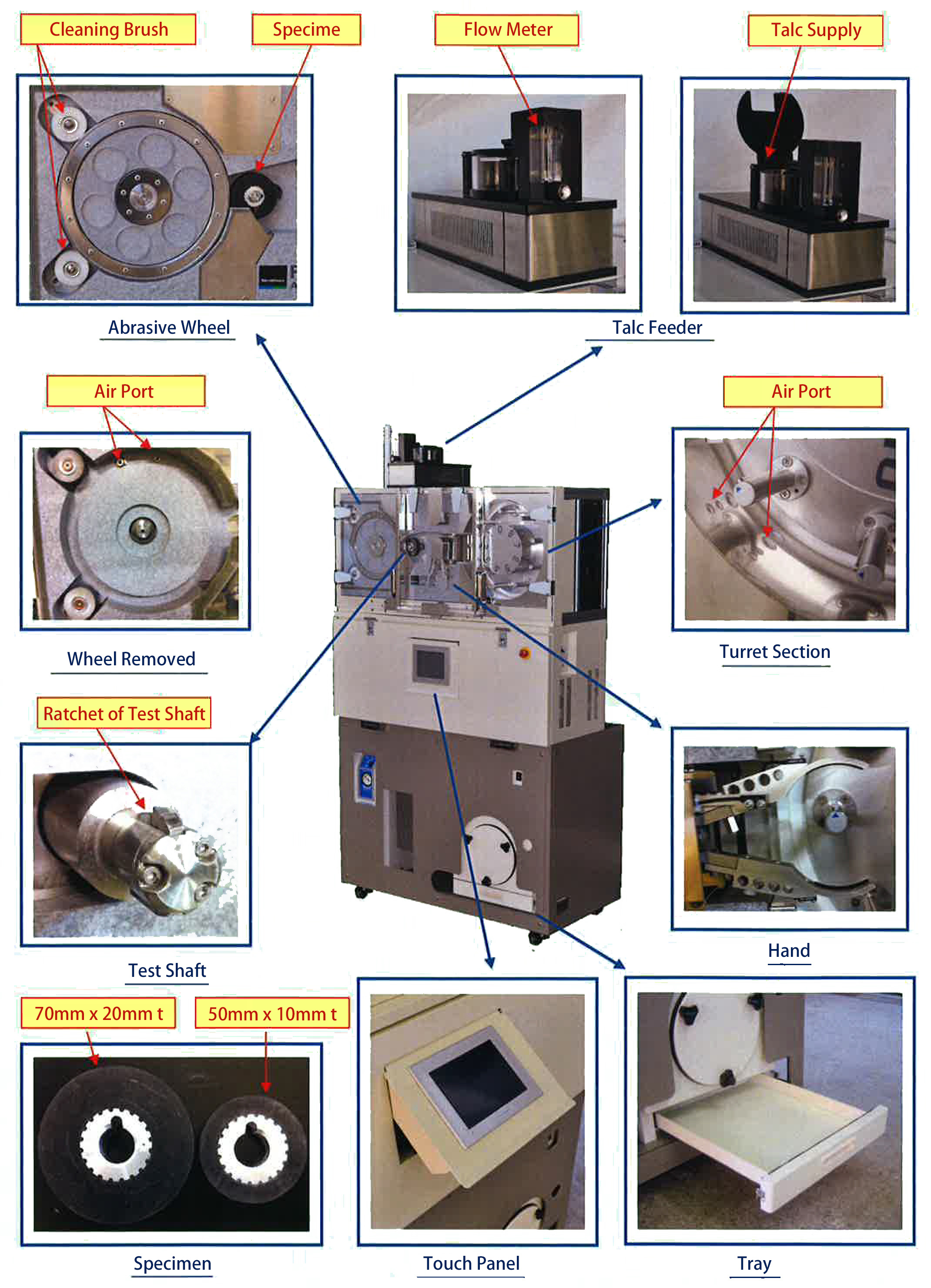

Details of Each Part

![]()

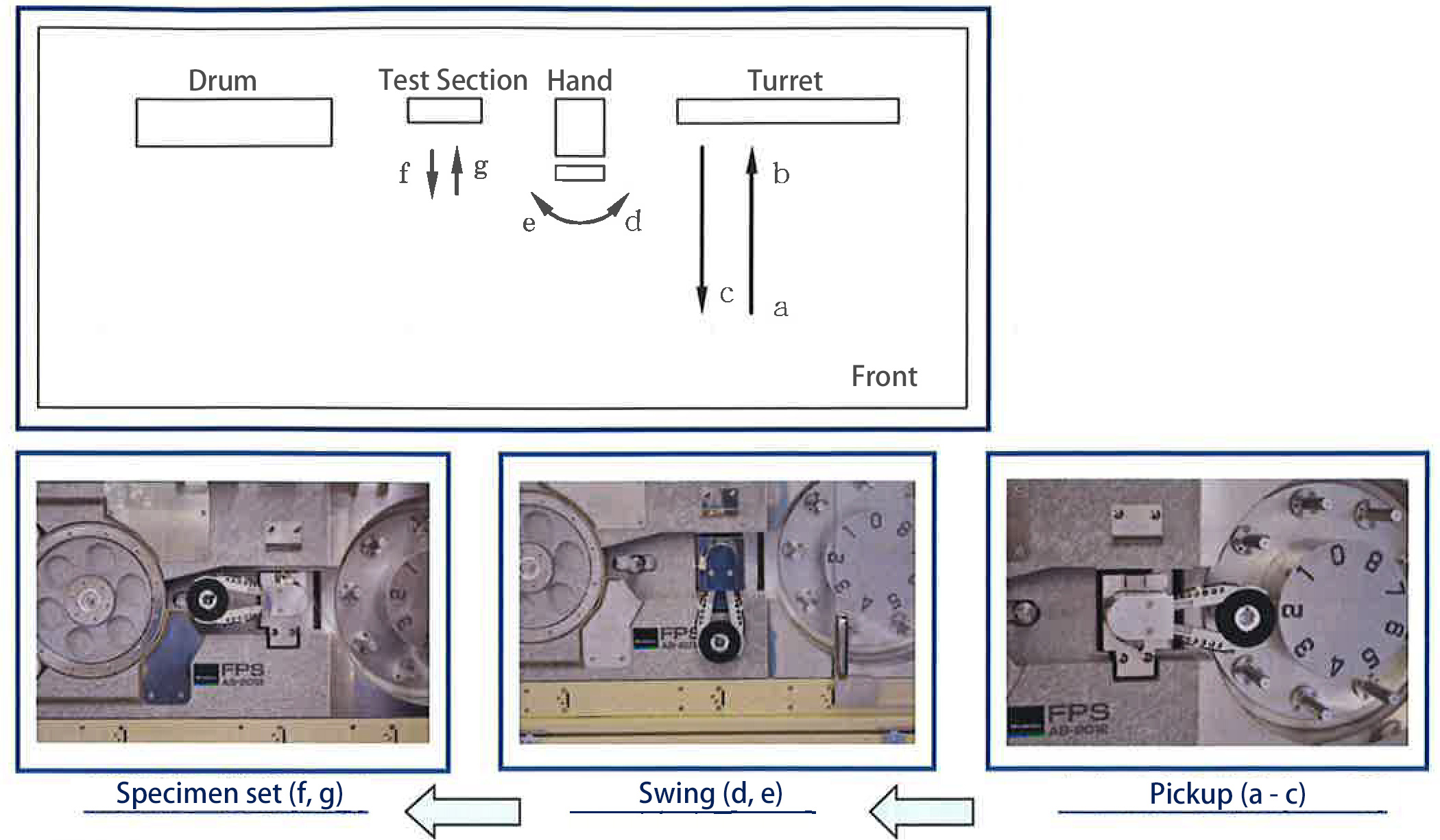

Transportation System

![]()

set it in the test section as shown.

After a test is complete, it will send back

the specimen to the turret and pick up

the next one for testing.

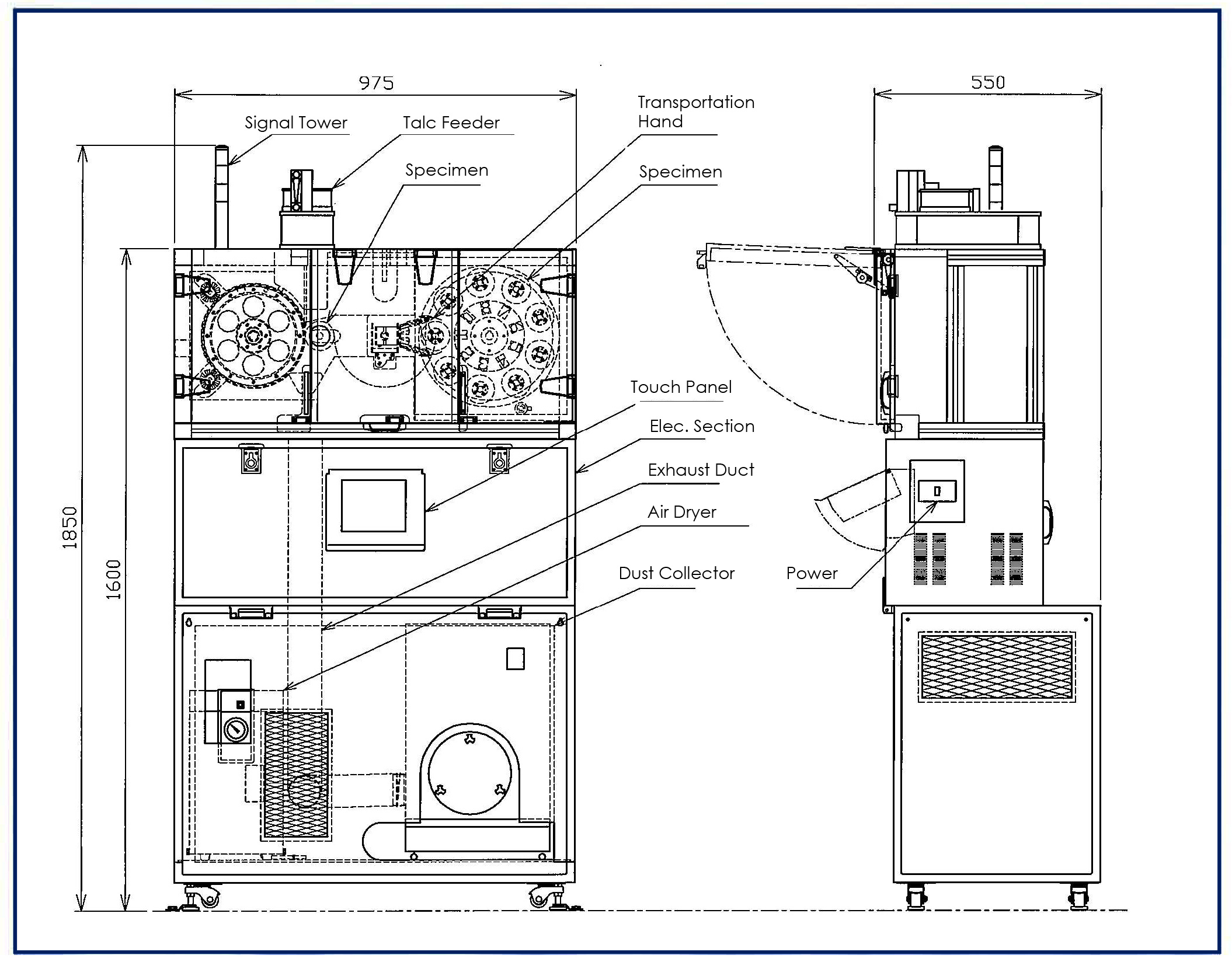

Appearance

![]()

Specifications

![]()

|

Name |

FPS Abrasion Tester |

|---|---|

|

Model |

AB-2012 |

|

Specimen Shape |

70-mm dia. x 20-mm thick, or 50-mm dia. x 10-mm thick (Factory option) |

|

Abrasive Wheel |

250-mm dia. x 30-mm thick (Abrasive: Safety Walk) |

|

Load |

10 to 80N ( Load cell rating: 100N) , Air servo load cell feedback method |

|

Torque |

±2.5N・m(Torque meter rating : ±3N・m) |

|

Slip Ratio Setting |

±20% |

|

Testing Velocity |

Specimen: 25 to 210 m/min, Abrasive Wheel: 35 to 150m/min |

|

Automatic Testing |

Automatic transportation and testing of specimens stored on the turret |

|

Continuous Operation |

64 (32) pcs max. for 50-mm (70-mm) dia. specimens |

|

Surface Temperature |

Non-contact thermometers (0 to 250ÅãC for specimen and abrasive wheel) |

|

Temperature Control |

Abrasive wheel (5 to 80ÅãC, optional) |

|

Dusting System |

Talc feeder (0.05 to 1.6rpm) |

|

Data Processing (PC) |

Condition setting, start/stop control, data acquisition, graph plotting, etc. |

|

Safety Device |

Emergency stop switch, door interlock, overload protection |

|

Utility |

Electric Power: 3-phs 200VAC, 30A 50/60Hz Dry Air: 0.5MPa or greater, 25L/min |

|

Usage Environment |

5 to 40ÅãC, 35 to 80% RH |

|

Dimensions & Weight |

Approx. 980(W)Å~1850(H)Å~560(D)mm, 320kg (incl. dust collector and air dryer) |

|

Accessories |

Dust collector, air dryer, calibration tool, core metals, etc. |

Options

![]()

![]() Electronic balance (with PC interface)

Electronic balance (with PC interface)

![]() Compact humidity conditioning case

Compact humidity conditioning case

![]() Temperature control of abrasive wheel (5 to 80°C) and specimen temperature conditioning on turret

Temperature control of abrasive wheel (5 to 80°C) and specimen temperature conditioning on turret

![]() Core metal inserter/remover

Core metal inserter/remover

![]() Spare abrasive wheel

Spare abrasive wheel

![]() Safety Walk (#240, #120)

Safety Walk (#240, #120)

Inquiries about FPS Abrasion Tester AB-2012

TEL.+81-42-572-1397

(Monday to Friday, 9:00 am to 5:00 pm Japan Time)

FAX.+81-42-573-1520